WPM Series

- Overview

- Features & Benefits

- Specifications

- Other Info

- Case Studies

Overview

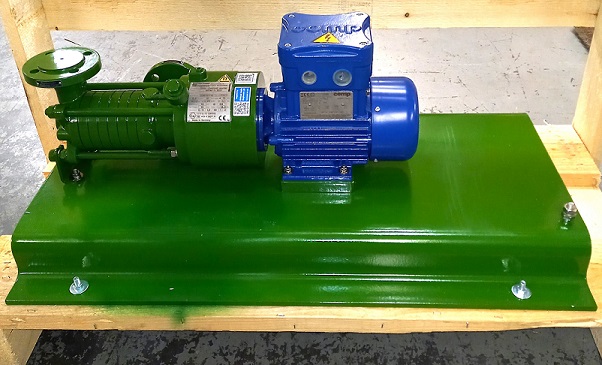

The Dickow WPM Series are self-priming, horizontal, side-channel pumps with end suction and vertical discharge flanges. The side-channel pump with its high differential head (achieved at low speed) has the advantage of operating more economically than standard centrifugal pumps for low capacities and high heads.

WPM Series pumps are suitable for handling clean liquids without solids in chemical and petrochemical industries. The pumps are also able to prime empty suction lines after initial filling with liquid. The static containment shell forms a closed system replacing double acting mechanical seals, along with external fluid reservoirs and the necessary control equipment.

The maximum operating temperature for standard designs is 150°C. The maximum operating pressure is 110 bar.

The single elements of the multipolar magnet coupling are manufactured of Neodymium-Iron-Boron with unlimited lifetime. The magnets in the driven rotor are completely encapsulated and not in contact with liquid. Power is transmitted to the hermetically sealed liquid end by a bank of external magnets. Inner and outer magnet rings are locked together by magnet forces and work as a synchronous coupling.

To achieve low NPSH-conditions, the impeller on the suction side has an enlarged eye area. The rotating star-shaped side-channel impellers are fitted in a chamber between the suction and pressure disk and keyed to the pump shaft in floating position. No hydraulic thrust load exists.

To achieve the self-priming capability, high efficiency and rated differential pressure, there are tight clearances between the rotating impeller and the stationary disks. During priming, a stable fluid film between the impellers and the disks centres the impeller in the chamber. In applications where prolonged dry-running can be a problem, or when handling volatile liquids with low viscosities, the pumps can be fitted with additional SiC-rings to avoid contact between the rotating and stationary parts.

The outer magnets are mounted directly on motor shaft. The internal slide bearing set consists of SiC bushing and a coated, metal shaft sleeve.

When coupled with Ex-drive motors, the pumps can be applied in hazardous area Group II, Category 2. The pumps meet the basic safety and health requirements of Explosionproof Directive 94/9 EC and are suitable for plants with increased safety requirements.