Useful Information on Peripheral/Turbine Pumps

What is a Peripheral Pump?

A peripheral pump, also called a turbine, vortex or regenerative pump, utilises a vaned impeller and is similar in concept to a side-channel pump. In terms of operation, peripheral pumps share characteristics with both centrifugal and positive displacement pumps. The pumping action arises from the complex transfer of energy as the fluid repeatedly interacts with the rotating impeller vanes and passes around a concentric channel in the casing.

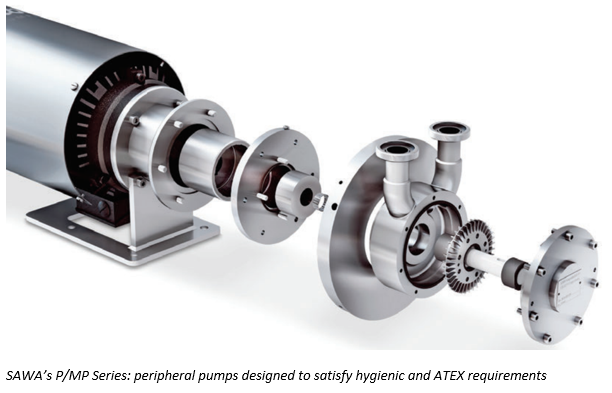

Peripheral pumps are commonly used in water supply and boiler systems, and for washing/spraying applications. They can also be used for pumping low viscosity chemicals, pharmaceuticals, cosmetics, beverages or foodstuffs and can fulfil ATEX requirements. Some single stage designs can fulfil hygienic requirements.

The pumps produce pulsation-free, low flows against high head pressures. They can tolerate entrained gases but are unable to self-prime without a self-priming chamber. The close tolerances between the impeller and casing do not allow the passage of solids so peripheral pumps can only be used with ‘clean’ liquids.

How does a Peripheral Pump work?

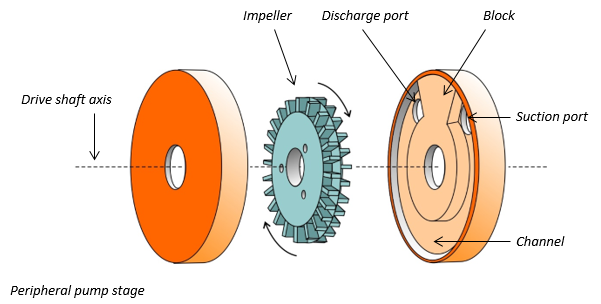

The key component of a peripheral pump is its impeller. Unlike a centrifugal pump, this consists of a large number of small vanes cut into the impeller’s outer rim. With vanes on each side, and with a number of holes cut through the body of the impeller, pressure imbalances during operation can be minimised. The impeller rotates adjacent to a channel in the casing within its sealing faces. The channel is blocked between the suction and discharge ports, so that fluid can be stripped out to the discharge port and stopped from returning to the suction side.

Unlike a centrifugal pump, fluid enters the system directly onto the vanes of the impeller rather than at its centre. Fluid is conveyed around the pump in the gaps between the vanes, much like a positive displacement pump. However, since there is no close contact between the vanes and casing, this alone could not produce a pumping action. Pressure arises from the strong transfer of energy as centrifugal force conveys the liquid in a complex helical flow around the vanes of the impeller, through the channel and around the casing.

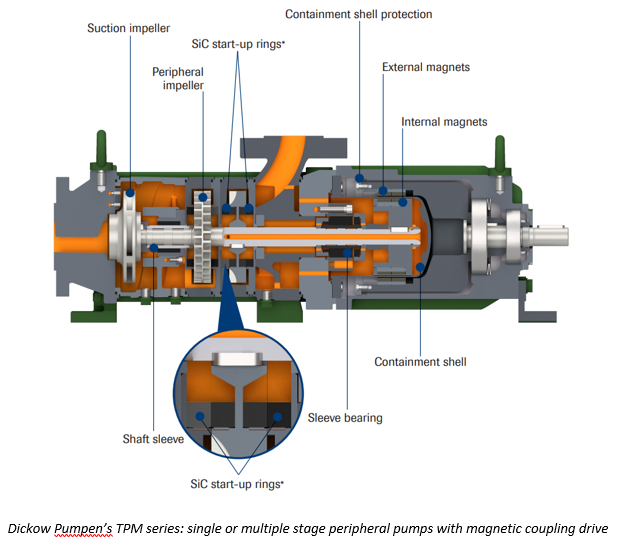

Peripheral pumps often use magnetic-drives providing a hermetically sealed, leak-free construction. This means no cross contamination of the pumped liquid, no process fluid wastage, no environmental hazards due to leaks, increased operator safety, reduced downtime, and less lost production.

What are the main benefits of a Peripheral Pump?

Peripheral pumps can generate high pressures with low flow rates. They have low NPSH requirements: the inlet pressure required for efficient operation is less than that of comparable centrifugal pumps. This makes them suitable for applications where liquids need to be pumped across long distances or through small pipework, such as the transfer of solvents, acids or other chemicals between vessels, or to circulate fluids in heating systems. Peripheral pumps can be manufactured for hygienic or ATEX applications.

Peripheral pumps are also ideal for working with pressurised liquids such as LPG. They are capable of pumping liquids with up to 20% gas content without any interruption to operation or damage to the impellers and are less vulnerable to cavitation than other pump types.

Peripheral pumps tend to be smaller and cheaper than other pump designs with similar capabilities and they also consume less power. The design is relatively simple with only a few components requiring servicing or maintenance.

What are the disadvantages of Peripheral Pumps?

Peripheral pumps cannot self-prime without the addition of other pump elements such as self-priming chambers. A self-priming chamber (also called a suction pot) is effectively a reservoir which holds sufficient liquid to flood the pumping elements of the pump. The design of the suction pot allows for air to be evacuated to a vent in the discharge line, pulling liquid into the chamber until the entire suction line is flooded.

Peripheral pumps should not be run dry and can be damaged if this happens. The pumps can be fitted with silicon carbide rings to stabilise the impeller and reduce wear.

Peripheral pumps can only be used with ‘clean’ liquids, free from solids. The small clearances between the impeller and casing make them susceptible to damage from any entrained, abrasive solids. Regular maintenance is important to avoid the build-up of contaminants.

What are the main applications for Peripheral Pumps?

Peripheral pumps are a popular solution for low flow, high head applications involving low viscosity, clean fluids. They are particularly suited to the handling of high temperature fluids such as in boiler feed applications and to the transfer of volatile chemicals. They are able to cope with fluids containing up to 20% gas - such as LPG.

Typical applications include:

- Chemicals:

- Acids, alkalis, methanol, ethanol, solvents, general chemicals

- Energy industry

- Liquid gas applications, condensate

- Tank farms & storage / Oil & Gas

- LPG, LNG

- Process industry

- Methanol production, thermal oil applications

- Foodstuffs and beverages

- Vinegar, concentrates, milk, mineral water, wine, spirits, beer, juices

- Pharmaceuticals, cosmetics and biotechnology applications

- Perfumes, emulsions, alcohols, dyes, herbal extracts, infusion solutions, purified water

Summary

A peripheral pump (also called a turbine, vortex or regenerative pump) utilises a vaned impeller, and is similar in principle to a side-channel pump. The impeller has a large number of small vanes cut into each side of its outer rim and rotates adjacent to a concentric channel in the casing. The pumping action arises from the complex transfer of energy as the fluid repeatedly interacts with the rotating impeller vanes and the channel.

Peripheral pumps generate high pressures with low flow rates and are ideal for working with volatile liquids such as LPG. They are capable of pumping liquids with up to 20% gas content without any interruption to operation and are less vulnerable to cavitation than centrifugal pumps.

Peripheral pumps cannot self-prime without the addition of other pump elements such as self-priming chambers. They should not be run dry and can only be used with ‘clean’ liquids, free from solids. Peripheral pumps tend to be smaller and cheaper than other pump designs with similar capabilities. The design is relatively simple with only a few components requiring servicing or maintenance.