Useful Information on Twin Screw Pumps

What is a Twin Screw pump?

A twin screw pump is a type of positive displacement pump comprising of two, parallel, intermeshed screws. With the synchronised rotation of the two screws, cavities are created along the pump’s axis and these allow the transfer of the pumped medium from suction to discharge in a controlled, non-pulsating flow.

Why Twin Screws?

Simple single screw pumps have been used for irrigation purposes for millennia. However, slippage is a problem with a basic single screw design making them unsuitable for industrial processes. The progressive cavity pump is essentially a modern version of a single screw pump. This uses a helical screw rotating eccentrically within a rubber sheath called a stator. The combined action of the helical screw and its contact with the flexible stator creates both a seal preventing slippage and a number of cavities to produce a low pulsation pumping action. This type of pump is commonly used for high-viscosity fluids and sludges containing abrasive solids. Stator wear is a problem, particularly in aggressive mediums, and progressive cavity pumps cannot fulfil high pressure requirements.

True screw pumps do not contain a stator. They feature two, three or multiple screws designed to intermesh closely without actually being in contact. Having three or more screws provides higher throughputs, better suction lift and smoother operation. However, the increased complexity can mean higher purchasing and maintenance costs. Twin screw systems are widely used because of their simpler design, smaller size and lower power requirements.

How does a Twin Screw Pump Work?

A twin screw pump consists of two parallel, intermeshing screws housed within a chamber. One screw is driven directly by the pump motor. The driven screw also powers the second screw through a gearing system. There is no direct contact between the two screws or the casing.

For efficient performance, the pump design requires close tolerances between the screws and casing. To reduce wear and corrosion, the construction usually involves advanced alloys, ceramics and coatings making them ideal for hygienic applications.

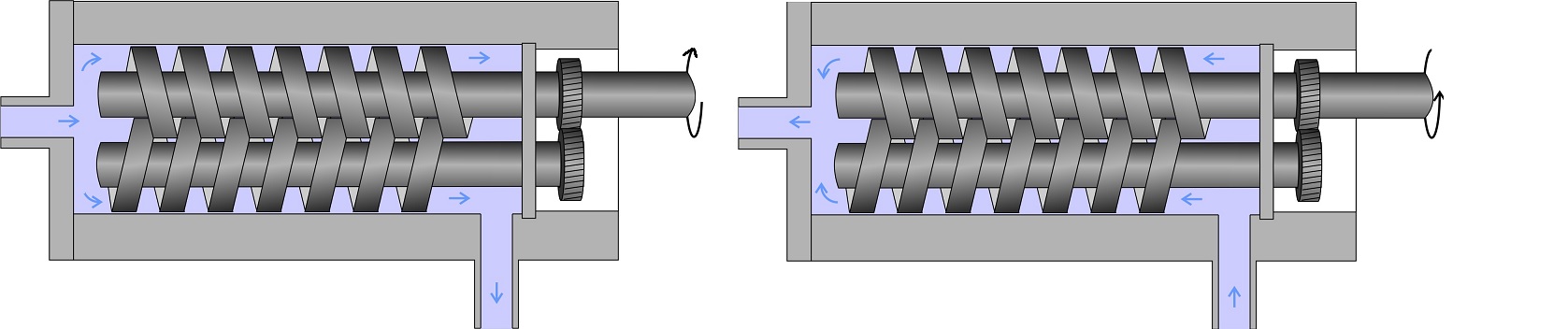

Schematic diagram of a twin screw pump: the ability to reverse the flow makes them more flexible, enables product to be recovered at the end of a production run and also aids cleaning

The synchronised rotation of the screws creates cavities between the screws and casing, which expand close to the inlet, creating suction, and contract at the discharge, creating pressure. The output is continuous, with little pulsation. It is controlled simply by pump speed. Also, since the fluid is moved axially there is little turbulence or foaming. The pumps are self-priming, bidirectional and can be run dry for limited periods. They operate effectively even with low inlet pressures and are quiet and vibration-free.

Twin screw pumps can also be designed to be double-ended. This provides better axial balancing of the rotating parts, further minimising the likelihood of any contact between the screws and casing that could result in wear or damage.

What are Twin Screw Pumps Used For?

Twin screw pumps are capable of handling most fluids, especially those with high viscosities or containing ‘soft’ solids such as sauces or ointments. They are used in refineries, mining, semiconductor and chemical industries, and waste water treatment. The pumps are capable of transferring petrochemicals, acids, alkalis, and other aggressive and corrosive fluids. In food, beverage, and pharmaceutical industries, twin screw pumps are particularly suitable for hygienic applications where cleanliness and sanitation are important. The gentle and controlled pumping action makes them ideal for delivering shear sensitive fluids.

The main disadvantage of screw pumps is that they are easily damaged by entrained, abrasive solids because of the close tolerances in their construction. They tend to be more expensive than comparable pump technologies, and are more difficult to maintain and repair.

Twin Screw Pumps for Hygienic Applications

Twin screw pumps featuring easy-to-clean components and high quality construction materials can be specifically designed for hygienic applications. The pumps allow easy disassembly and cleaning, are self-draining, and have the advantages of being non-contact, having flushed seals and external gearings and bearings. The same pump can be used for both the process and cleaning cycles and the flow can be reversed to avoid product wastage before a cleaning cycle.

Cutaway view of Bornemann Hygienic Twin Screw pump SLH-5G

Summary

Twin screw pumps are a type of positive displacement pump comprising two intermeshed but non-contacting screws. Pump performance relies on the close tolerances between the screws and casing. Through the synchronised rotation of the twin screws, the expanding and contracting gaps between them facilitate the transfer of the pumped medium from suction to discharge in a gentle, controlled, low shear, low pulsation flow.

Twin screw pumps are capable of handling most fluids and are used in many industries including petrochemicals, food and beverage, pharmaceuticals, semiconductors, mining and sewerage. With easy-to-clean components and high quality construction materials the pumps can be suitable for hygienic applications.