Useful information on pumps for isocyanates and polyols

Chemicals used in the production of polyurethane foam?

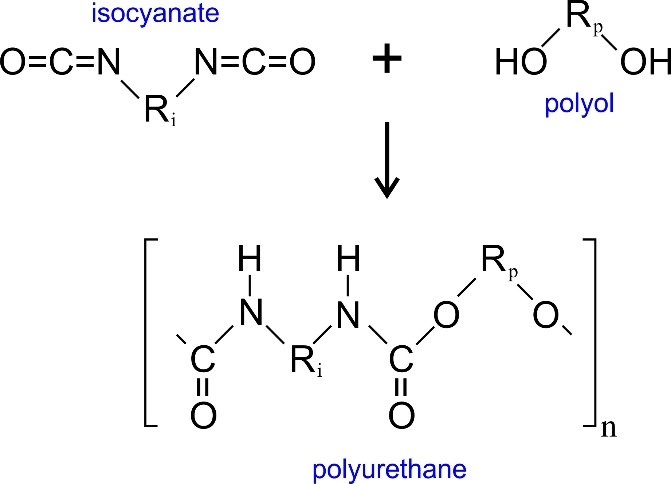

Polyurethane foam is a versatile polymer widely used for insulation, cushioning (in mattresses, furniture and vehicle seats), packaging and soundproofing. It is produced by a thermosetting chemical reaction between a polyol and one or more isocyanates.

Commonly used isocyanates are the aromatic di-isocyanates: toluene di-isocyanate (TDI) and methylene diphenyl di-isocyanate (MDI). TDI is primarily used in the production of low-density flexible foams whereas MDI is a more complex mixture and is used to make rigid foams.

Polyols are usually hydroxyl-terminated polyethers or polyesters. The polyol selected determines the degree of cross-linking. Diols, polyols containing two hydroxyl groups, produce a linear polymer. Polyols with more than two hydroxy groups result in more crosslinking and a firmer product.

How is polyurethane foam made?

Flexible low density foams (such as those used for insulation and sound-proofing) are produced in a continuous conveyor process, with the isocyanate and polyol reagents sprayed onto foil or paper and allowed to rise and cure. When set, the resulting low density foam can be cut into the required size and shape. For medium density and rigid polyurethane foams, such as those used for furniture, the reactants are combined and formed to the required shape in moulds. By careful choice of reagents, process conditions and methods, polyurethane can be tailored for many applications.

What are the problems?

The process involves the separate delivery and subsequent mixing of an isocyanate mixture (commonly called Side A) and a polyol blend (Side B).

Isocyanates pose significant health hazards, being a cause of occupational asthma, irritation of the respiratory system and skin irritation and dermatitis. Some isocyanates are suspected of being carcinogens. In spraying processes, aerosols might be inhaled or come in contact with the eyes or skin. Potential exposures may occur through skin contact or inhalation of particulates and dust. Isocyanates are also flammable. It’s therefore important to employ a delivery system free from leaks.

Isocyanates react with water producing CO2 and amines, and the latter can react further with isocyanate to form polyurea – an abrasive solid. Water is sometimes added to the polyol blend as a blowing agent - the CO2 bubbles from the resulting reaction creating the foam’s cell structure. However, uncontrolled exposure to moisture can cause problems and affect product quality. Within the isocyanate delivery system, it is important to avoid moisture. Any reactions in the pumps and pipework can result in particulates, blockages and cavitation.

Polyol blends contain blowing agents (water, or various hydrocarbons) which determine the cell structure, catalysts to promote the reaction, surfactants and, in some cases, flame retardants. Polyols are hygroscopic and will carry any moisture into the polyurethane production process where it can react with isocyanate and may cause problems during curing. Other than this, the polyol blend is relatively inert requiring no special precautions.

Which pumps are suitable?

For the polyurethane process there are two primary pumping requirements: polyol and isocyanate delivery. In both cases, accurate, pulse-free metering is crucial for controlling product quality. Gear, diaphragm and vane pumps are generally preferred for these tasks.

Pumps for Isocyanate

Isocyanates can be thin or viscous depending on composition and are poorly lubricating. Double mechanical seal solutions with seal support systems can be used but the choice of seal material is crucial. Isocyanates can degrade some seal materials causing them to become brittle or swell resulting in loss of flexibility and sealing capability. Innovative solutions such as Viking’s O-Pro barrier seal system have been used successfully. This consists of a series of FFKM O-rings, with the seal area filled with a compatible barrier grease.

However, all mechanical seals are prone to deterioration under these conditions: the isocyanate will react with any moisture present in the air at the boundary of the shaft seal, ‘setting’ on seal faces, and causing distortion of the seal. Over time, this may seize the shaft leading to expensive repairs or complete pump replacement. If a pump fitted with any type of mechanical seal is selected, regular inspection and replacement of seals is essential to prevent failures and ensure safe and effective operation.

The safest solution for isocyanate transfer is to use magnetically coupled ‘sealless’ gear pumps or diaphragm pumps. In these systems, the pump chamber is completely sealed, preventing moisture from entering and reacting with the isocyanate, and also preventing leakage of the toxic chemical.

It is still important to consider the compatibility of all wetted parts. Silicon carbide bearings are recommended. Some additives used in isocyanate feeds can affect bronze and carbon graphite bushings, whereas any entrained solids could erode carbon graphite bearings. Isocyanate itself is not typically corrosive to metals, so a cast iron pump construction is generally acceptable.

Careful choice of the O-ring/gasket material is necessary. Isocyanates are highly reactive and can attack the polymer chains of many elastomers. This can result in the degradation of an O-ring/gasket with cracking, swelling or shrinkage and loss of elasticity. PTFE/Teflon, Kalrez, or EPDM are recommended whereas Nitrile or Viton are typically not compatible, and their use should be avoided.

Some examples of suitable pump systems for dosing isocyanate are:

- Viking Pump's internal gear pumps, a range of cast iron pumps with magnetic drives.

- Liquiflo’s external gear pumps, magnetically coupled stainless steel gear pumps

- Wanner’s Hydra-Cell range, diaphragm pumps featuring a hermetically sealed pumping chamber so there are no seals, packing or cups to leak or replace. Low pulse flow.

- FTI Air, air-operated diaphragm pumps with no internal seals or moving parts

Pumps for polyols

The polyol feed is usually less problematic, and a wide range of pumps can be considered for this task. Polyols are relatively inert requiring fewer precautions. Although some polyols can cause skin and eye irritation, unlike isocyanates, they are not toxic. It is not generally necessary to have sealless pumps with magnetic drives; mechanical seals can usually be used, but this does depend on the specific application and the particular polyol. Some polyol blends contain abrasive fillers that can damage pump components, particularly mechanical seal faces. Also, although polyols are hygroscopic and will absorb moisture, they do not react with water in the same way as isocyanates. However, in some circumstances water absorption must be avoided to ensure product quality and so a mag-drive pump may be the most suitable option.

Internal gear pumps are ideal for transferring and dosing polyols (for example, Viking’s H124A shown above). They are versatile, being capable of operating across a wide range of fluid viscosities and temperatures, and with feeds that may contain solids. Polyols used in polyurethane manufacture tend to have a high viscosity and have good lubricating properties. Depending on their structure, a polyol blend can have a viscosity anywhere between 100 and 200,000 mPas. Internal gear pumps are also good for accurate and reproducible metering.

Summary

Polyurethane foam is widely used for insulation, cushioning (in mattresses, furniture and vehicle seats), packaging and soundproofing. It is made by mixing two chemicals: an isocyanate and a polyol blend. Isocyanates are highly reactive with water and many of the materials typically used for pump seals. They are toxic, and also flammable. Sealless pumps are recommended to minimise the chance of leakages or problems with moisture reactions. Polyol blends are less problematic but tend to have high viscosities. Internal gear pumps are ideal for this purpose.

Selecting the right pump for polyurethane foam production presents unique challenges due to the nature of the chemicals involved. Therefore, careful consideration is essential when choosing pumps to ensure safety and reliability. At Michael Smith Engineers Ltd, we have decades of experience in this field and have supplied pumps to all leading manufacturers of polyurethane foam insulation and related products.