Side Channel vs Peripheral/Turbine

Side Channel and Peripheral (or Turbine) pumps are similar in concept and capabilities. Both systems are sometimes described simply - and wrongly - as centrifugal pumps. Although they share many similarities with centrifugal pumps, with centrifugal action being important in the development of their pumping characteristics, they also have other aspects more akin to positive displacement pumps. More confusion arises from the multiple names used to describe them: side channel pumps are also known as ‘liquid ring’ pumps; alternative names for peripheral pumps are ‘turbine’, ‘vortex’, or ‘regenerative’ pumps.

This article compares the two technologies including their relative advantages and disadvantages.

How does a Side Channel Pump work?

There are two aspects to the operation of a side channel pump. Under normal conditions, when the pump is filled with liquid, it performs in a similar manner to a centrifugal pump. When starting up, with a partially filled pump and empty suction line, a side channel pump operates like a positive displacement pump generating suction lift and expelling vapour or air.

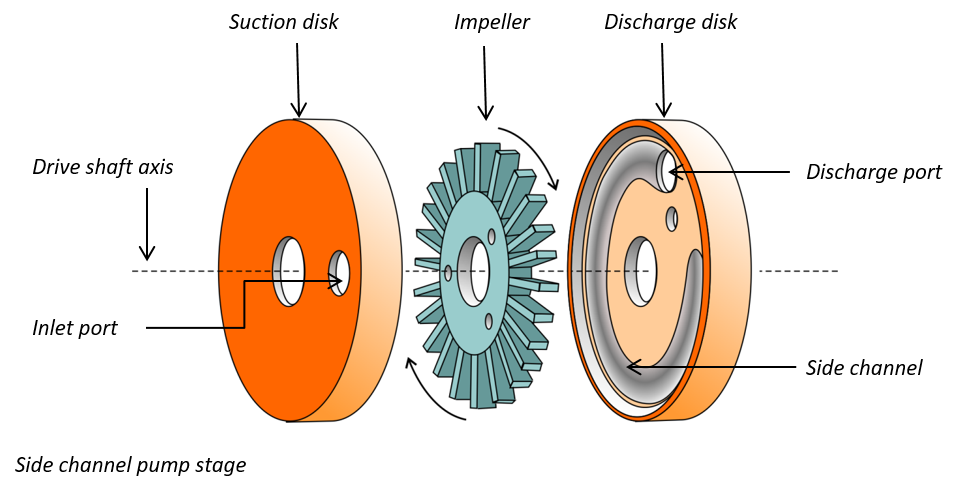

The key components of a side channel pump stage (there can be multiple stages) are the suction disk, impeller, and discharge disk. The suction disk has a port to admit liquid and has a role in supporting and aligning the impeller. Impellers are star-shaped with multiple, straight vanes. The discharge stage has a circular groove cut into the inside face. This is the ‘side channel’, which extends most of the way around the discharge disk and is tapered towards the discharge port, with a reducing cross-section. The discharge port allows liquid to pass out of the stage – either to the suction disk of a successive stage or to the pump’s discharge flange.

How does a Peripheral Pump work?

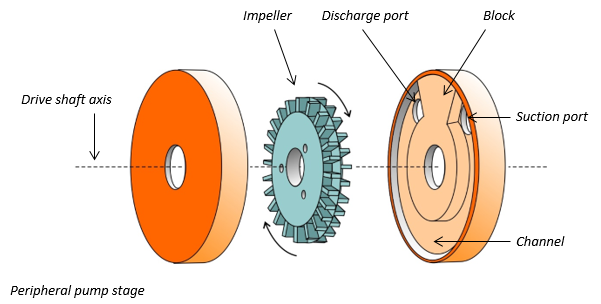

In a peripheral pump, the impeller has a larger number of small vanes cut into its outer rim. The impeller rotates adjacent to a channel in the casing within its sealing faces. The channel is blocked between the suction and discharge ports, so that fluid can be stripped out to the discharge port and stopped from returning to the suction side. With vanes on each side, and with a number of holes cut through the body of the impeller, pressure imbalances during operation are minimised.

Fluid enters the system directly onto the vanes of the impeller. It is conveyed around the pump in the gaps between the vanes, much like a positive displacement pump. However, this alone could not produce a pumping action. Pressure arises from the strong transfer of energy as centrifugal force conveys the liquid in a complex helical flow around the vanes of the impeller, through and around the channel.

What do Side Channel and Peripheral Pumps have in common?

Side channel and peripheral pumps both have lower NPSH requirements than comparable rotodynamic pumps. Both pump types are efficient and economical solutions for applications requiring the pumping of low volumes of liquids at high differential pressures, or where liquids need to be pumped across long distances or through small pipework.

Both pump types are capable of pumping liquids with high levels of gas content without any interruption to operation or damage to the impellers. They are less vulnerable to cavitation compared to centrifugal pumps. Side channel pumps in particular are preferred when working with pressurised liquids such as LPG or heated liquids close to their boiling point.

Side channel and peripheral pumps can only be used with ‘clean’ liquids, free from solids. The small clearances between their impellers and casing make them susceptible to damage from any entrained, abrasive solids. Regular maintenance is important to avoid the build-up of contaminants.

How do Side Channel and Peripheral Pumps differ?

Only side channel pumps can self-prime, so they are suitable for applications such as the emptying of fuel tanks. With a vertical pump design, a side channel pump can be mounted directly onto a storage tank, minimising and simplifying the suction-side pipework. Peripheral pumps cannot self-prime without the addition of other pump elements such as self-priming chambers.

Side channel pumps typically require more stages (and are hence larger) to achieve the same pressure capability offered by a peripheral pump. Peripheral pumps therefore tend to be cheaper. With a simpler design and construction they are generally easier to service and maintain.

Summary

Side channel and peripheral pumps have lower NPSH requirements than other pump technologies. They can both generate high pressures with low flow rates and are ideal for working with volatile liquids such as LPG. They are capable of pumping liquids with high levels of gas content without any interruption to operation and are less vulnerable to cavitation than other pump types. Side channel pumps in particular are ideal for pumping fluids that are at or near their boiling point.

Both pump types can only be used with ‘clean’ liquids, free from solids. The small clearances between their impellers and casing make them susceptible to damage from any entrained, abrasive solids. Regular maintenance is important to avoid the build-up of contaminants.

Side channel pumps are capable of self-priming, but this is not possible with peripheral pumps without the addition of a priming chamber. Peripheral pumps tend to be smaller, easier to maintain, and cheaper than side channel pumps.

|

|

|

|

| SAWA Hygienic Peripheral Pumps | SAWA Hygienic Side-Channel Pumps | Dickow TPM Peripheral Pump | Dickow Side Channel Pump |